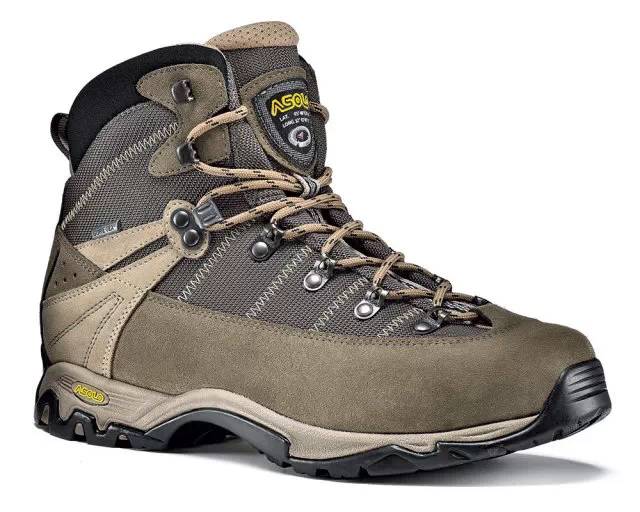

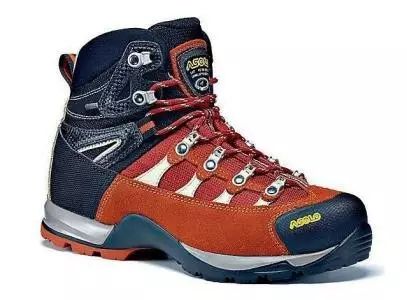

Advantages: The boots produced in this way are sturdy and durable, with larger space in the boots, and are more comfortable to wear. If the sole of the boot is worn out, you can also replace it with a new sole.

Disadvantages: The problem is that if the needle eye of the suture is large, the shoe is more likely to open due to wear, or corrode the nylon thread due to water penetration. In order to solve this problem, some manufacturers have added a layer of leather to the sealing between the production middle surface and the boot sole to enhance the wear resistance and sealing performance of the seam, while also increasing the comfort of the foot in the boot. For example, Italian company products are all made by using this process and manual sewing. In addition, in order to meet the different needs of the market, these companies have designed different types of shoe lasts based on their long-term shoemaking experience and the different characteristics of Asian and European races and male and female foot shapes, in order to produce different types of shoes for different races and genders. Adopt the overall adhesive method: the boot surface and sole are integrally bonded by a machine. Advantages: This process method has low production cost, large production volume, and low price. Disadvantages: Their firmness varies greatly, mainly depending on the process used in the production process and the quality of the adhesive. Some low-end hiking shoes or boots are produced using this process.

Pure leather fabric

advantage:

Good waterproof performance, high wear resistance, and better protection for the foot surface than nylon, suitable for long-distance outdoor treks, carrying heavier climbing equipment, and climbing relatively hard mountain climbers.

Disadvantages:

Its own weight is heavier than nylon, and its breathability is not as good as nylon boots. Wearing shoes is time-consuming.

Rigid plastic resin

Advantages: It is relatively hard and has good rigidity, which can effectively protect the safety of the feet. High mountain climbing boots are made of this resin material.

Disadvantages: Large size, heavy weight, cumbersome to wear and take off, time-consuming and laborious. For example, snowboarding boots produced by companies such as Asolo and Scarpa, and snowboarding boots produced by companies such as Crispi and Garmont all use this material.

Lining materials for mountaineering shoes The lining materials in boots are usually synthetic textile fabrics, which are lightweight and contain waterproof molecules to prevent water from entering the shoes. At the same time, the materials need to have breathability to keep the skin on the upper of the foot dry.

Common fabrics

Gore-Tex -- A special fabric that is very soft and comfortable, breathable, waterproof, windproof, and wear-resistant, produced by Gore-Tex Company in the United States. This material is used in mid to high-end hiking boots. Gore-Tex material is different from traditional shoe materials such as rubber and leather. It is a composite material produced using high-tech technology. The outer layer of the cloth can prevent rainwater immersion and wind penetration. The cloth contains a waterproof breathable carrier, which can volatilize sweat from the inner layer, and has breathability from the inside out. Due to its light weight, this material is widely used in the manufacture of shoe linings, outdoor sports clothing, gloves, and so on.

Sympa Tex - a multi layered, anti static, non porous fabric that undergoes special chemical and physical treatment to prevent the immersion of rain and wind; In other words, it is a waterproof and breathable film. With breathability, it can quickly absorb sweat on the skin surface and evaporate rapidly. It contains synthetic molecules to prevent mold and odor from soaking into the fabric. Its performance and principle are basically the same as Gore-Tex and are produced by the Italian company SympaTex. Many high and middle grade hiking boots use this material.

Gambrelle - A synthetic chemical fiber fabric with characteristics such as mildew resistance, hygiene, and abrasion resistance. It can quickly absorb sweat and odor from the feet, evaporate quickly, and keep the feet dry. Its performance is superior to the above two fabrics. Many alpine hiking boots use this fabric. This product is produced by DuPont Corporation of the United States.

VertigoGrip - Its performance is basically the same as Cambrelle, but its softness is better than Cambrelle, and its application range is relatively wide. Sheepskin - With good softness, it is also a traditional lining that is more comfortable, but has less breathability than the synthetic fabrics mentioned above. AirTech - A synthetic material that contains a variety of pore structures, can absorb sweat and gas from the surface of the skin, has good breathability, is hygienic, and lightweight. It is commonly used as a lining for boot uppers.

Insole/outsole

"Inner sole: A foot board that directly contacts a person, usually made of softer nylon material. The shape design is based on the characteristics of the person's foot shape. Some also insert a thin steel plate between the inner sole and the outer sole, coated with a corrosion resistant coating, and padded with a piece of leather.". Different models of hiking boots have different insole designs and materials, as well as different comfort levels. Some mountain climbing boots also have a midsole between the inner and outer soles, in addition to an inner sole. The midsole is also made of nylon synthetic material, with a moisture content that has a shockproof cushioning microporous structure.

Outsole: Directly in contact with the ground, usually made of synthetic rubber materials. Different manufacturers use different synthetic materials, but their purpose is to effectively protect the foot and increase comfort resistance. The heel is relatively low, lightweight, and non-slip, with irregular grooves on the underside to prevent sliding

Vibram soles and mid to high-end mountaineering boots all use the outsole produced by the Italian Vibram company. Because Vibeam not only provides professional materials, but also provides professional outsole pattern design. Due to the development and application of new materials every year, Vibeam has always been a synonym for high performance, high skills, and high comfort. Therefore, Vibeam enjoys a high reputation and credibility in the outdoor industry. Vibram soles are made of hard synthetic rubber materials, with the greatest characteristics of skid resistance and shock absorption. At the same time, rubber also has characteristics such as non oil adhesion and flame resistance. Rubber itself is a kind of anti-skid material, which is pressed into irregular shapes based on engineering materials, creating a bumpy bottom surface to generate greater friction. Vibram's bottom has different design styles, and its groove direction, depth, and material are designed to meet the needs of different types of hiking boots. For example, non viscous and flame resistant soles are designed for engineering shoes, hard and abrasion resistant soles are designed for hiking boots, ice claw grooved soles are designed for snowy hiking boots in half, and softer soles are designed for casual shoes for everyday wear. Vibram also uses the latest modern technology to add shock absorbing micropores to the soles High strength carbon fiber and other high-tech materials.