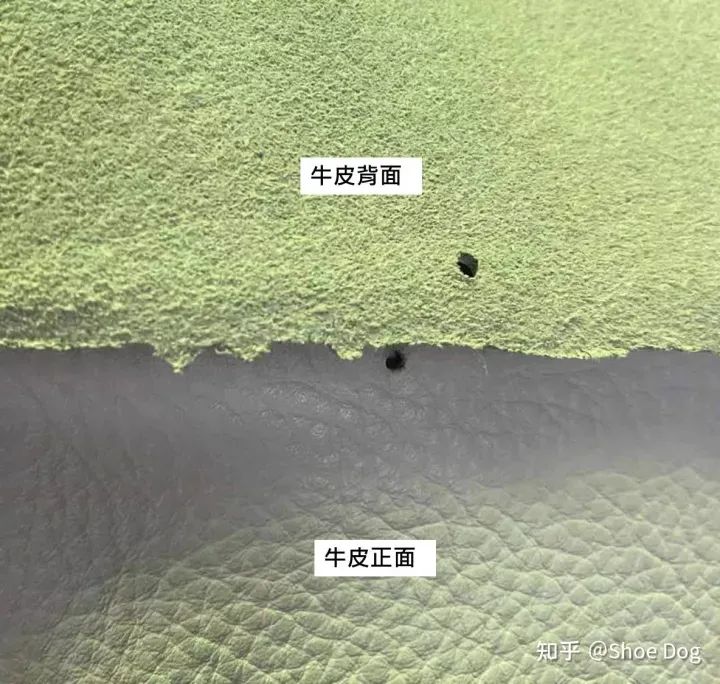

In addition, the type, origin, age, gender, climate, area size, thickness, weight grade, fat content, sweat glands and blood vessels, as well as the density of hair, all directly affect the price and performance of cowhide.

Reverse fur or flipping. The surface of the suede has the characteristics of primitive animal skin, with fur, unevenness, good texture, good breathability, soft touch, comfortable wearing, and can be dyed in various colors through the core. But its shortcomings are poor color fixation, easy to dirty, and difficult to maintain. Its poor color fixation requires that when designing shoes, reverse fur should not be paired with materials with contrasting colors, otherwise it is easy to cause color overflow problems. For example, dark suede should not be paired with light colored materials, and vice versa.

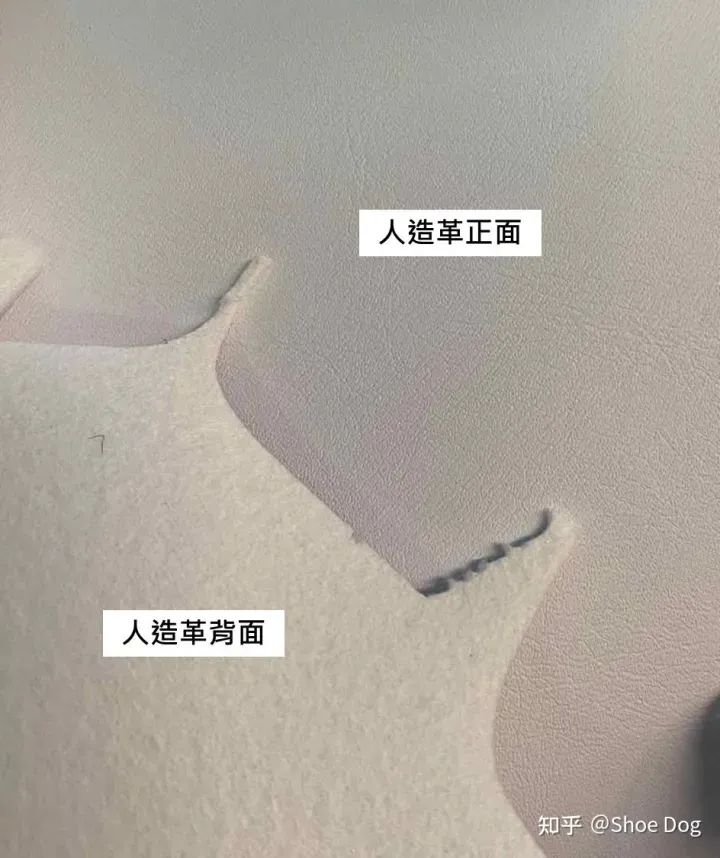

2. Artificial leather

It is made from various formulas of PVC, PU, and other foam or film covering on a textile or non-woven fabric base. It can be processed according to different strength and color, luster, pattern patterns, and other requirements. It has the characteristics of a wide variety of colors, good waterproof performance, neat edges, high utilization rate, and relatively cheap price compared to genuine leather. But the vast majority of artificial leather cannot achieve the feel and elasticity of genuine leather.

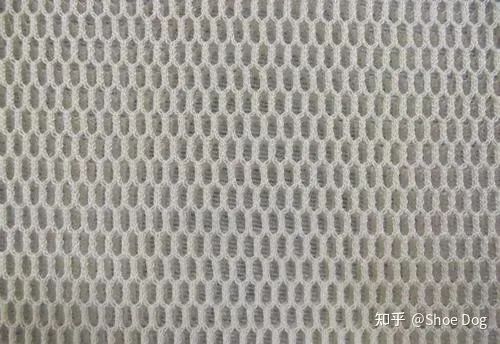

3. Mesh fabric

Used in the exposed area of the shoe upper, it is lightweight and has good breathability, softness, comfortable wearing, and resistance to bending. The disadvantage is that it does not keep warm. For example, sandwich mesh. The lightweight and breathable properties of mesh are very suitable for making surface materials such as running shoes and training shoes.

4. Foam

Foam has the characteristics of good elasticity, light weight, good rebound and bending. Usually used at the collar (heel area) and tongue area to increase comfort. Many types of shoes also use 2mm foam inside the waist to increase comfort and breathability, as well as enhance the three-dimensional feel of the waist. Foam usually uses quality to indicate tightness, and a high quality of foam indicates that the voids inside are small, resulting in a higher density. For example, 30kg foam refers to a cubic meter sponge weighing 30kg; 50kg foam refers to 50kg/m ³。

Due to the poor friction and tear resistance of foam, it is usually not used for exposure and needs to be bonded with other materials. Usually, during the homework process, self-adhesive (adhesive and release paper) is applied first, and it can be easily and quickly adhered to other components by simply tearing off the release paper.

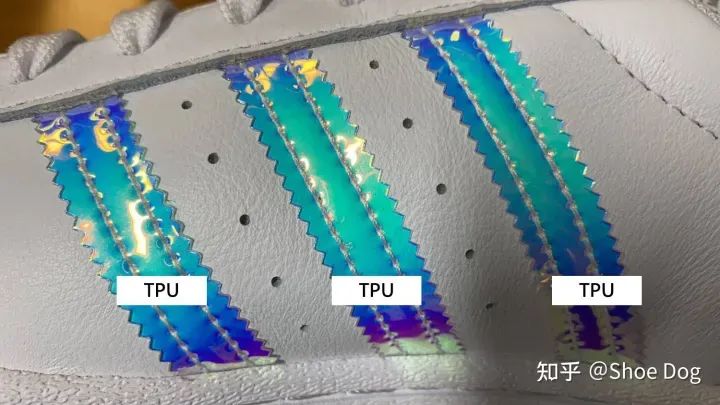

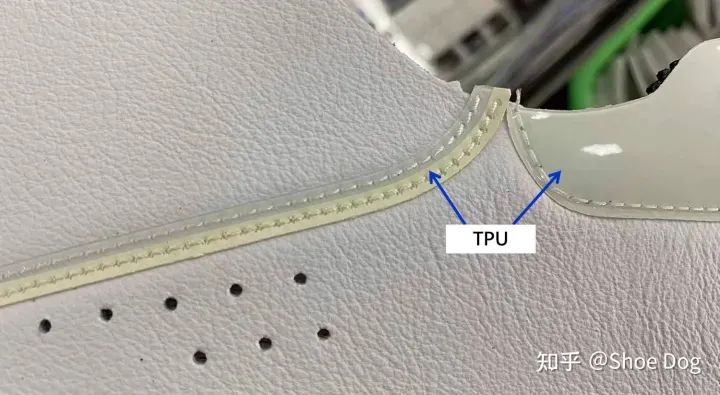

5. TPU

TPU is a hard but easily flexible plastic material with good support and protection, mainly used on various types of uppers, which effectively strengthens the good support for the upper.